Fixie 3D specialises in creating beautifully crafted 3D architectural models using a combination of 3D printing models and traditional modelmaking.

We have extensive experience in the architectural sector and knowledge of how best to prepare 3D CAD files for 3D printing. Based on this, we can advise you on how to best prepare your architecture 3D model and suggest the optimal combination of 3D printing service London and model making.

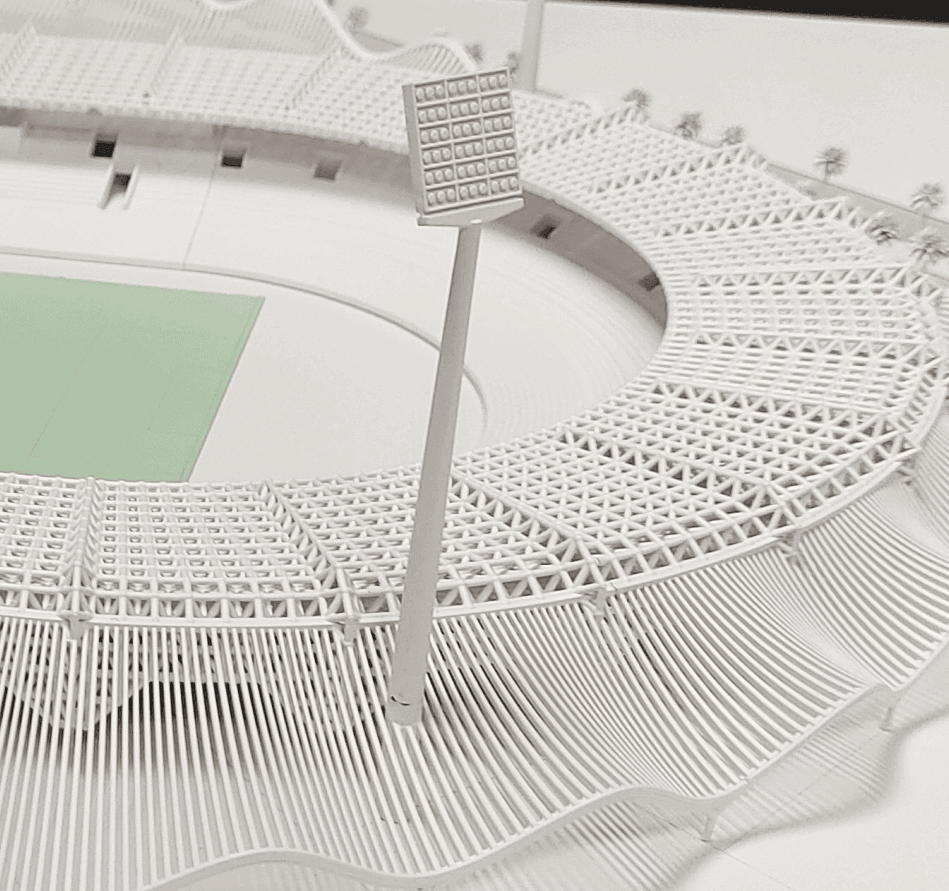

Our 3D printing technicians and model makers are experts in advising on the most suitable processes, taking into account project finish, timescale, and budget. For our architecture 3D models, we mainly use stereolithography (SLA) technology because of its exceptional detail and smooth print, which is perfect for spray painting and model-making finishes. The large build platform of 750 x 750 x 550mm also allows for large architecture 3D models that can be further assembled after by our model maker.

If you have a 2D, CAD, or BIM file that you need to turn into a real-life physical model, send it to us, and we'll figure out the best way to make it happen!

Why Fixie 3D use 3D printing combined with model making for Your 3D architecture Model?

Faster Turnarounds

3D printing can quickly produce complex curves and details, which, when combined with the skills of a model maker, can expedite the model-making process overall and produce a more affordable 3D architecture model.

Highly Detailed Models

3D printing models created with stereolithography, which uses laser technology, have finer, smoother details than models created with other 3D printing technologies.

Large scale Models

Our stereolithography technology - build size 750 x 750 x 550mm is ideal for creating large format 3D printing Tiles can be combined to create a larger architecture 3D model.

Creative model making

Our team of model makers understands how to best combine architecture 3D models and traditional model-making techniques to create the best possible solution for your 3D architecture model.

3D file Preparation expertise

Our team of file fixing experts can prepare your 3D files for 3D model architecture. We can thicken parts without adding bulk, close spaces where necessary, and advise you on creating the best possible files for 3D printing.

Comprehensive finishing

Choose from a wide range of materials to replicate concrete, glass, metal, and more. Our model makers finishing options, including painting, assembly, and mounting, ensure your models are presentation-ready.

Model: Stadium - highly detailed

Model: Golden Lane - smooth finish for spray painting

Our large format printer 750 x 750 x 550mm

Our 3D Architecture Model Services

Context model with inserts - Corstophine + Wright

Context plug models

Create one-off context 3D printing of the development area and design an array of plug options to speed up design decisions

Context model with level of detail - 4

high detail BIM models

3D printing service directly from your building information models - export STL or FBX and our 3D file fixers will prepare your files for 3D printing

Interior fit-out model KB Architecture

3D Floor Plans and fit out

Create interactive 3D floor plans and house models that help clients visualise spaces and make informed decisions.

Pre-planning hospital model

Pre-planning models

Architectural plans can be submitted as 3D printing models for pre-planning approvals.

Competition model Mossessian Architecture

Competition Models

Our competition models can be designed to be compact and convenient, easily fitting as hand luggage for travel.

Model created with Kandor Modelmakers

Marketing Models

Higher end 3D architecture models with more model making finishes to sell development potential to clients.

How Fixie 3D Helps Architects Like You

Project for STW Architects

Enhance Client Presentations: Create a compelling 3D architecture model that captivate your clients and clearly communicate your vision.

Streamline Design Development: Use 3D printed models for iterative design exploration, identifying potential issues early in the process.

Win Competitions: Stand out in architectural competitions with an impactful 3D architecture model that showcase your creativity and technical expertise.

Communicate Complex Designs: Effectively convey complex spatial relationships and architectural details with our precision 3D printing.

We like to ensure that our models offer maximum utility - creating a site plug in the initial model allows you to print numerous updates as the design evolves. Your model therefore becomes an efficient design tool, documenting the narrative of the project’s development.

Each additional plug adds to the material used and therefore the cost of the model will also increase proportionally.

Tools and Technologies We Use

At Fixie 3D, we utilise Materialise Magics for preparing and optimising your architectural files, we accept Revit, AutoCAD, Rhino, and SketchUp exported to STL. OBJ or FBX. Our 2D -3D conversions are created using advanced 3D modeling tools like Rhino or Revit.

Your Trusted Partner for 3D Model Architecture

Whether you’re looking for professional 3D model printing, architectural model making services, or large format 3D printing for architecture, Fixie 3D is your trusted 3d printing service partner. We combine cutting-edge technology, expertise, and exceptional customer service to deliver cost-effective and high-quality solutions tailored to your needs.

Get Started Today

Ready to elevate your architectural projects with precision 3D model architecture? Contact Fixie 3D, one of the top companies in 3d printing and your UK 3d Printing Service Partner today to discuss your requirements and discover how we can help you achieve your goals.

Notes

If you have prints that exceed the maximum build size we can split your model over multiple builds.

All care is taken to conceal the split lines where possible.

If you'd like to know more please get in touch via