Fixie secured aN Innovate UK grant to deliver automation that makes 3D printing an accessible and affordable tool for all architects.

Press Release: Monday, November 23, 2020.

Fixie, an innovative 3D printing firm, has secured £100,000 in funding from Innovate UK to build an automated online platform that will drastically cut the time it takes for architects to create physical models from their digital 3D designs.

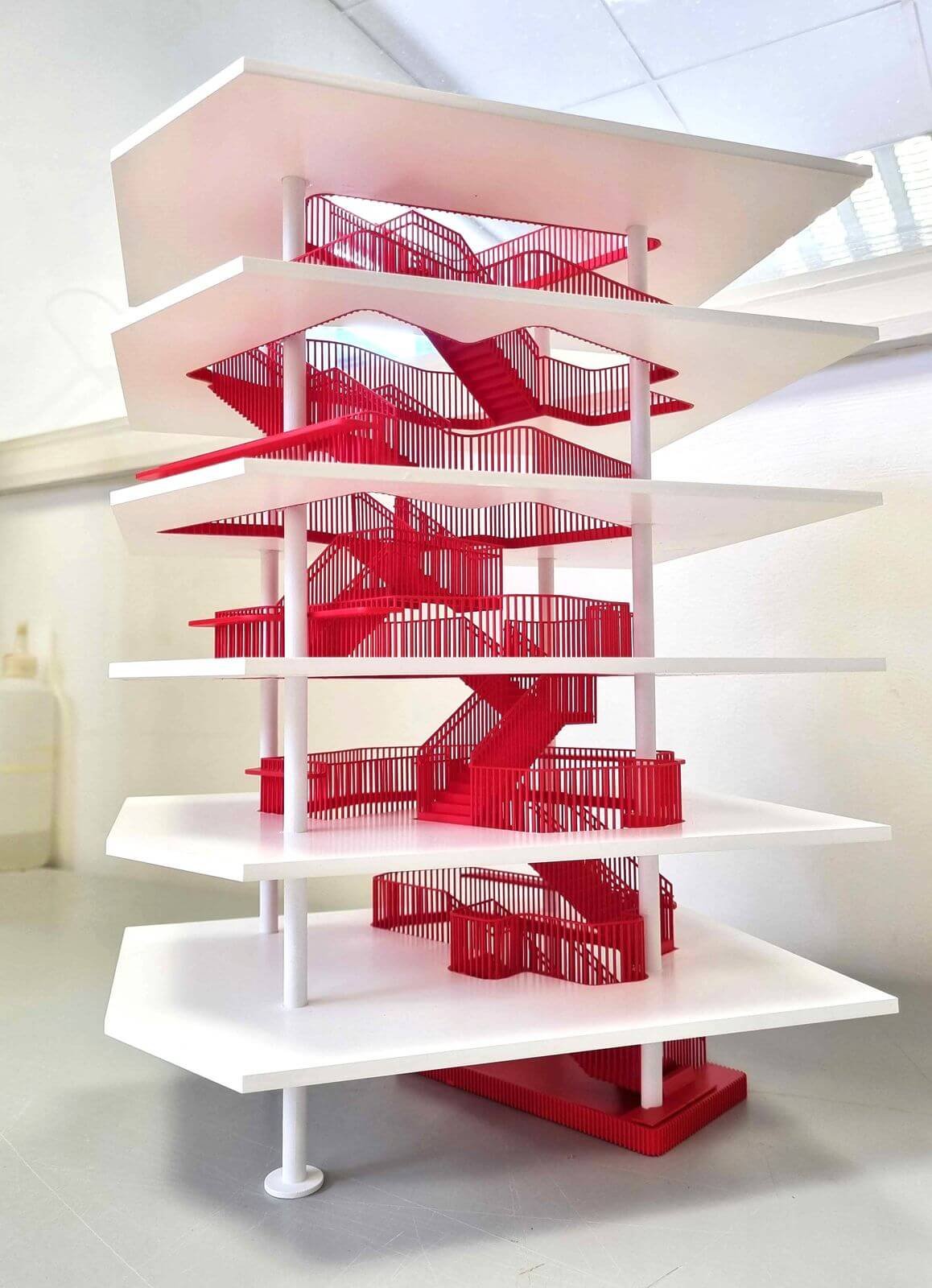

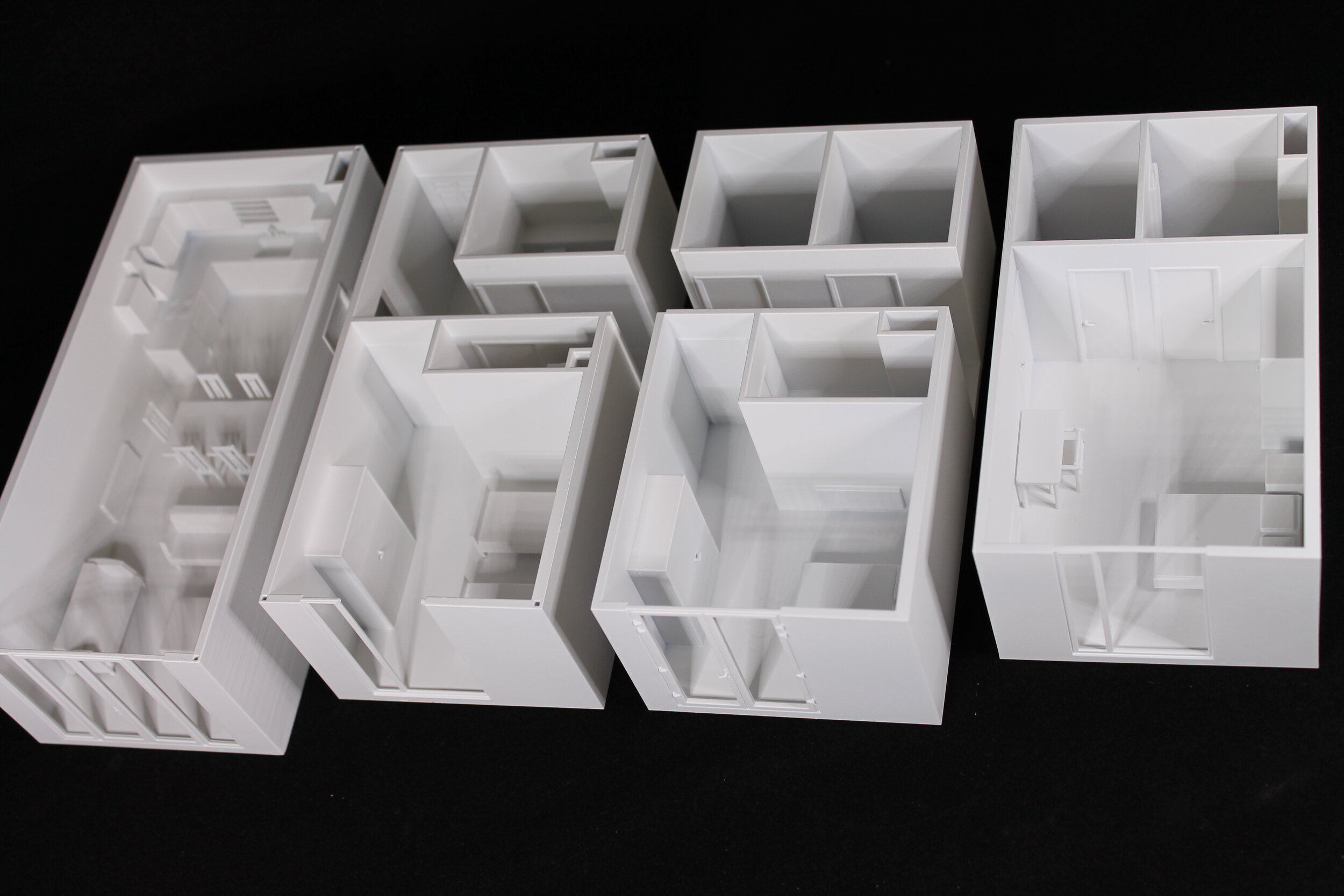

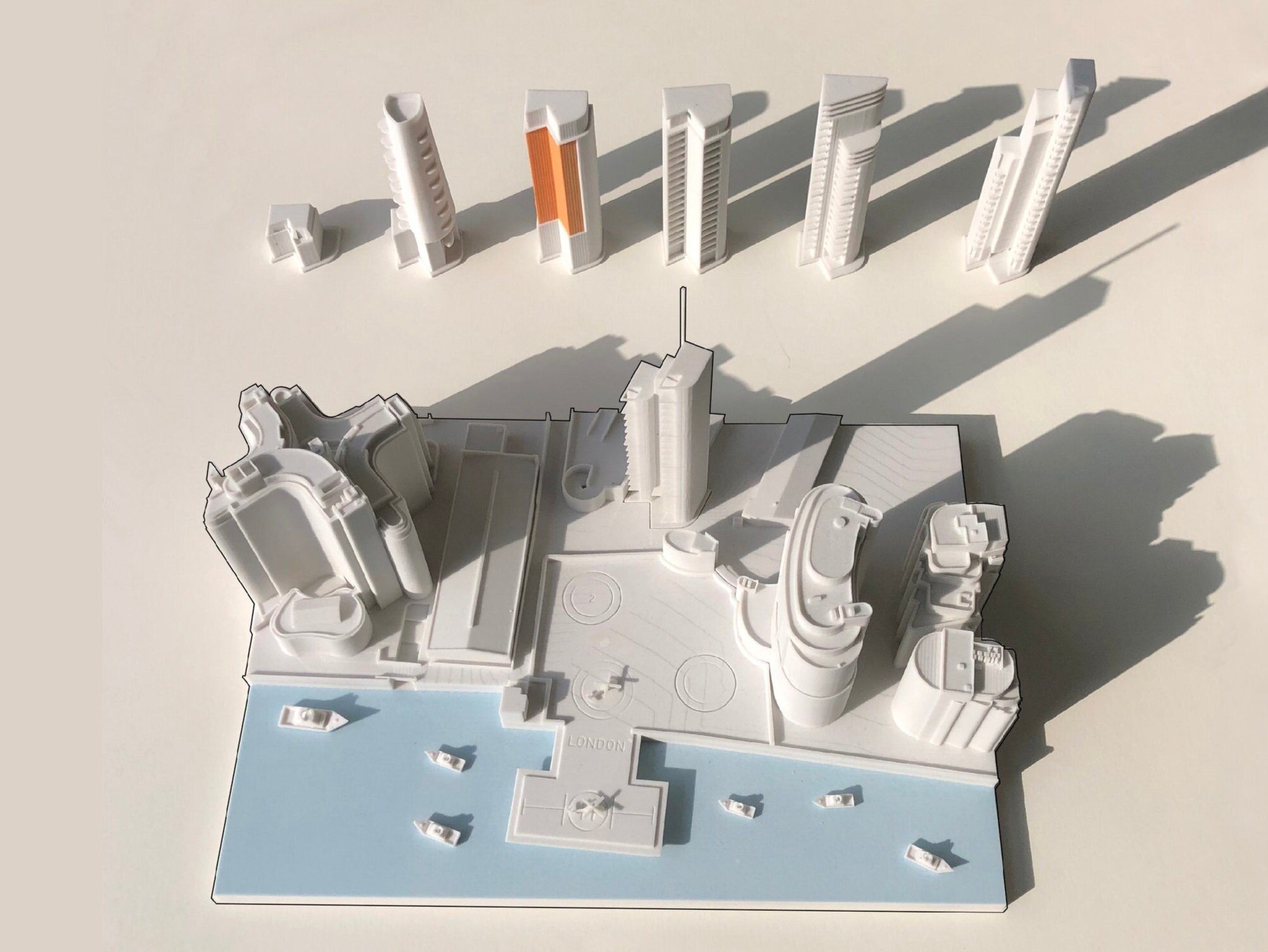

Fixie’s platform simplifies the architectural 3D printing process by eliminating the need for arduous remodelling which can currently take days to convert an architects’ design to a 3D printable version. The company, which focuses on the architectural sector, will be supported by the University of Sheffield Advanced Manufacturing Research Centre (AMRC) on the project.

“We started Fixie to give more architects the opportunity to benefit from rapid prototyping. Our platform means that you don’t need to have any prior knowledge to prepare your design for 3D printing - opening up the technology to those without the niche skills, time and resources.” Ronan O’Boyle, one of the founders said.

Innovate UK, as part of UK Research and Innovation, is investing up to £191 million to fund single and collaborative research and development projects as part of the Sustainable Innovation Fund over the next two years. The aim of these competitions is to help all sectors of the UK rebuild after the effects of COVID-19.

The Sustainable Innovation Fund is funding 1,103 projects, 1189 UK businesses and totalling over £130 million in support across the UK.

Michelle Greeff, Fixie CEO said:

“This grant award recognises the potential social and economic impact of Fixie’s platform at a time when architects are rethinking how cities are used and designed. It’s an endorsement of our vision and the commitment to providing architects with tools to make practical and wider use of emerging technologies.”

The University of Sheffield AMRC is a network of world-leading research and innovation centres that work with manufacturing companies of all sizes around the globe. The organisation, part of the High Value Manufacturing (HVM) Catapult, transforms industrial and economic performance by making step changes in productivity, increasing competitiveness, developing new products and processes and training new talent and skills.

Head of Digital at the University of Sheffield AMRC, Professor Rab Scott, said: “This is a hugely important project which is at the heart of what the AMRC has built its reputation on: transforming industry through collaborative research.

“Through the application of digital tools, architects will be able to produce digital 3D designs in hours rather than days. The development of this vital platform, increasing speed and cutting costs for the supply chain, will both enhance the sustainability of how businesses deliver for their clients and add value across the construction and built environment sector.”

Innovate UK Executive Chair Dr Ian Campbell said:

“In these difficult times we have seen the best of British business innovation. The pandemic is not just a health emergency but one that impacts society and the economy.”

“Fixie, along with every initiative Innovate UK has supported through this fund, is an important step forward in driving sustainable economic development. Each one is also helping to realise the ambitions of hard-working people.”

Fixie – architects’ 3D printing assistant – helps architects communicate their projects through 3D printing.

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) is a world-class centre for research into advanced manufacturing technologies used in the aerospace, automotive, medical and other high-value manufacturing sectors.

The AMRC has a global reputation for helping companies overcome manufacturing problems and is a model for collaborative research involving universities, academics and industry worldwide.

Combining state of the art technologies with the AMRC’s expertise in design and prototyping, machining, casting, welding, additive manufacturing, composites, robotics and automation, digital manufacturing and structural testing, has created a manufacturing resource far beyond anything previously available in the UK.

The AMRC is a member of the High Value Manufacturing (HVM) Catapult, a consortium of leading manufacturing and process research centres, backed by the UK’s innovation agency, Innovate UK.

Innovate UK drives productivity and economic growth by supporting businesses to develop and realise the potential of new ideas.

Innovate UK connects businesses to the partners, customers and investors that can help them turn ideas into commercially successful products and services and business growth, funding business and research collaborations to accelerate innovation and drive business investment into R&D.

Support is available to businesses across all economic sectors, value chains and UK regions. Innovate UK is part of UK Research and Innovation.

Contact:

Ronan O’Boyle, Co-founder

Email: ronan@fixie3d.com

Phone: +447427380639

Fixie Website:

www.fixie3d.com

Fixie Twitter:

https://twitter.com/Fixie3D

Fixie LinkedIn

https://www.linkedin.com/company/fixie-3d

Fixie Instagram:

https://www.instagram.com/fixie3d/