Fixing and 3D printing a colour interior model

As you may have seen on our Instagram we were recently working with a colourful interior fit out model. It brought up a few more issues than we anticipated and we’d therefore like to share how we overcame them.

(This is a specific use case of how a file is fixed - for a less technical description please follow our Fixing Series which supports live project descriptions with a more general overview of 3D printing and file fixing principles).

Starting Point

The model was originally created in SketchUp and imported directly into our file preparation software. The textures/colours applied in SketchUp are also conveniently imported (This can be both a blessing and a curse, as often heavy textures can slow down our software).

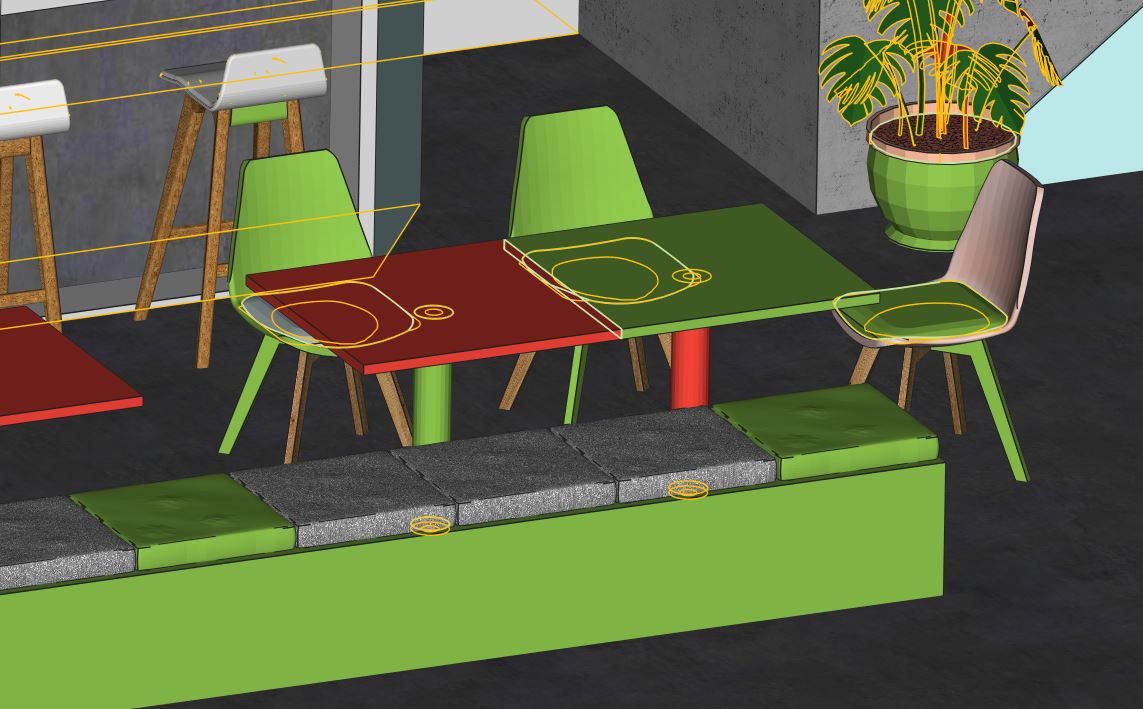

The imported model is run through a diagnostics check. This reveals all the errors in the model which have to be fixed before it is printable. As you can see in the image below this model has multiple errors indicated by the coloured lines: Bad Edges, in yellow, which occur when triangles/surfaces are not properly connected leading to gaps in the model mesh and Flipped triangles/surfaces are in red.

Single surfaces will not survive post processing or even print at all. All surfaces need to have a thickness in order for them to work in the 3D printing process. Part thickness is determined by all the connected surfaces creating a shell. All parts must be one complete shell with no bad surfaces or holes in order for them to print.

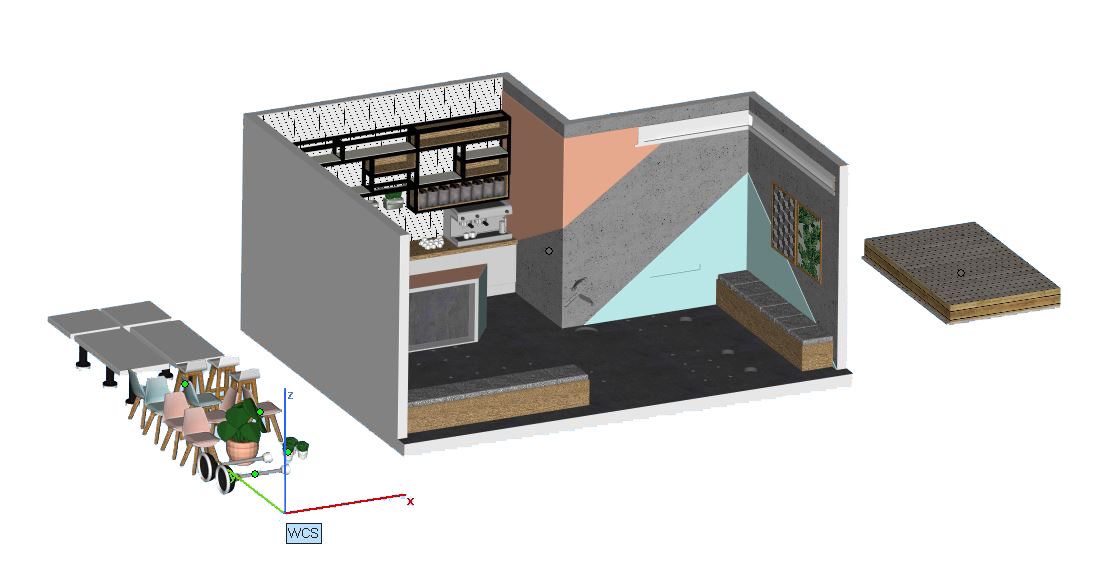

A model can be made up of multiple shells like those displayed in the image above in green. Even a simple object like a chair can be made up of multiple separate shells (the legs, the back, the cushion, right down to the screws if you have sent us some delightfully detailed information). In order for the part to print correctly and not fall apart in the process, shells will need to be unified to make one single shell.

The ultimate goal for any model is to create a single shell with no holes, bad edges or no inverted surfaces - in other words: no errors whatsoever!

File Fixing, like life, is all about breaking things down into manageable chunks to make it all seem achievable. Once the model has been split into manageable parts, each can be fixed individually, one at a time.

POST PROCESSING

Breaking down a model can also help to improve the overall finish of the model as it allows access to areas that require post possessing (hand finishing and brushing) after printing. All parts can be finished individually and assembled to bring the model together. We do also 3D print models all in one piece, but breaking them down like this gives flexibility to do more with a model.

Another benefit to breaking the model up in CJP gypsum powder printing is what we call Infiltration. This is the process of letting glue seep into the porous powder to give it strength and also make the saturated colour come to life!

When gluing a model it is vital that all surfaces have been brushed meticulously in order to remove any surface material that has not been removed using compressed air. If the uncured surface material is not removed the end results will show up as very patchy and give a bleach like stain on the models surface.

It’s equally important that when parts are being infiltrated with cyanoacrylate that the process is done quickly and efficiently to avoid the the infiltrant drying at different speeds. This would result in shiny patches also referred to as Double Gluing. All excess glue should be removed from the surface before drying to reduce the possibility of the shiny effects mentioned.

Infiltrated parts should be left to dry thoroughly before handling. Moisture will react with the drying process and can result in white patches on the model (the natural oils on your fingers can leave a mark at this stage, so keep those hands off!)

As for aftercare, it’s important never to get a CJP gypsum powder model wet. Water will react with the material and again cause a bleaching effect (white spots). Similarly, placing the model in direct sunlight will cause a CJP 3D printed model to discolour over time.

We hope that wasn’t too much to take in and that with our supporting blogs will help you make sense of the work that we do for your models at Fixie. If you’d like to know more, we’d love to hear from you directly on info@fixie3d.com