“Let's talk about fixing, for 3D.

Let's talk about your file, and see.

Let's talk about all the good things and the bad things, that may be.

Let’s talk about…”

Inspired by Salt N Pepa

We most likely have your attention now, which is important because the scintillating subject of architectural file preparation for 3D printing awaits you; a few simple steps that will save you from many a restless night (‘Did I really turn off all the layers?’). If you follow this procedure closely then 3D printing will be as much a compliment to your design process as Salt was to Pepa.

Whatever the design stage or the audience, a model is a powerful decision-making tool: offering the ability to see your design in the real world; to touch it; interrogate it and compare it. Unfortunately understanding what is possible, within the timeframe and especially within the budget is not always black and white. To provide you with these answers we need to be supplied with relevant design information and your preferences for how your design should be communicated.

Providing Information for an accurate Quotation

This won’t be the last time we mention this, but we have built a web-based tool for exactly this purpose.

1_HOUSEKEEPING

First things first, it’s important to be organised to help avoid any confusion with ongoing design work, so save a copy of your design file.

a_Create a New Folder:

e.g. “Fixie Quote”

“Fixie 3D Printing Quote”

“I Heart Fixie”

In this folder save a packaged file of your model here. This will ensure that all referenced drawings that are relevant for a quotation are also included in the information that you send to us.

b_Name the file appropriately:

Naming the file for quotation differently will always help to avoid confusion.

e.g drawingname_fixiequote.extension

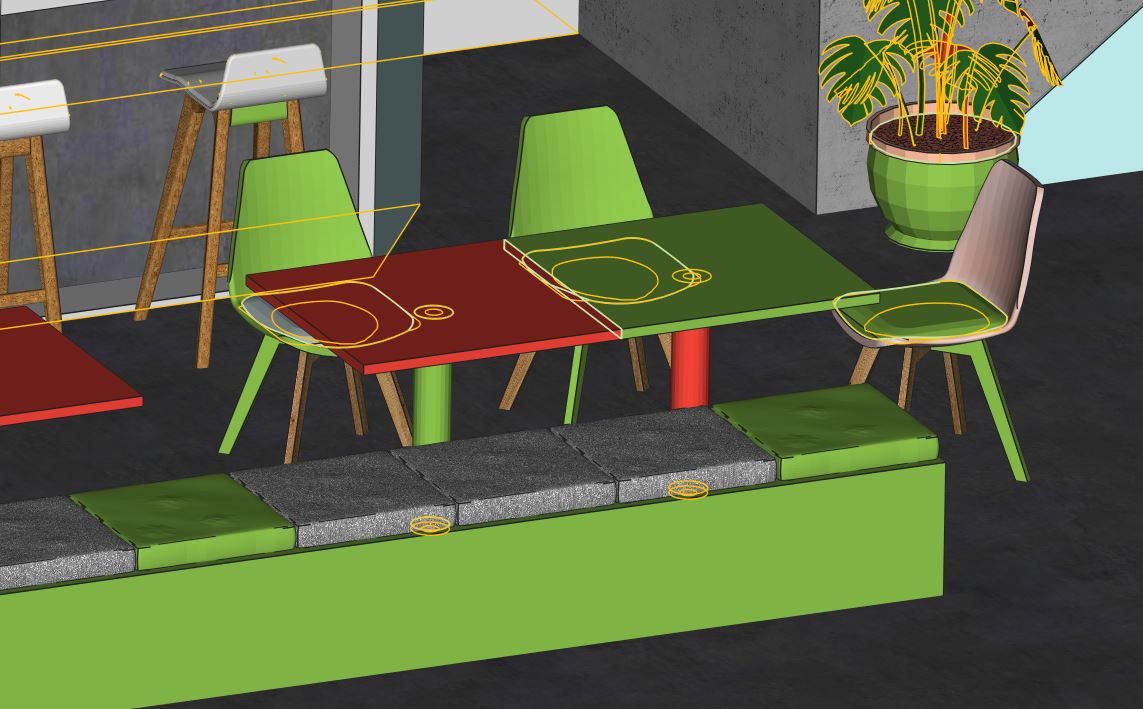

2_Taking out the TRASH: File Clean-Up

Now it’s time to clean up this new file - all of these steps will help speed up the quotation process and, later on, the fixing process itself. It will also ensure that no unwanted information is printed or equally that no time is wasted working on elements which aren’t important.

We all know what makes a file heavy, even if we try to turn a blind eye to the beautiful million polygon trees we’ve imported for “atmosphere”. Let’s run through some of these items:

a_people

No

b_furniture

No again

c_toilets

Noooooooo

d_Sculptural artwork you’ve downloaded from 3D warehouse

😐

In general, the message here is to think about the relevance of the information provided to achieving the final print. If you have a tight deadline, then the sooner we can assess the file and get fixing, the more likely that deadline will be met. A lighter file allows this to happen, so turn off, or preferably delete, those unwanted layers and detail (sometimes non visible/turned off layers will still be imported into our software).

e_trees

Not unlike the superfluous details above; trees can really slow down files and more often than not they’re actually 2D components and therefore will not print. Depending on whether you want trees included in your model or not, the following approaches apply:

3D Printed Trees: Supply trees in the model (up to 1-1000)

Traditional Trees (added by hand): Do not supply trees in the model - a separate tree plan will suffice.

No Trees: Do not supply trees in the model

f_context

It’s pretty amazing that we now have entire cities modelled in 3D. A lot of time can be wasted zooming in and out on a Friday afternoon whilst trying to look busy. However, we don’t need all of London to be uploaded for you to get a cost for your 3D print. And don’t worry we’re still very impressed with the size of your data.

Any and all context data that is not going to appear in the print should be removed or it will add time to delivering at each milestone.

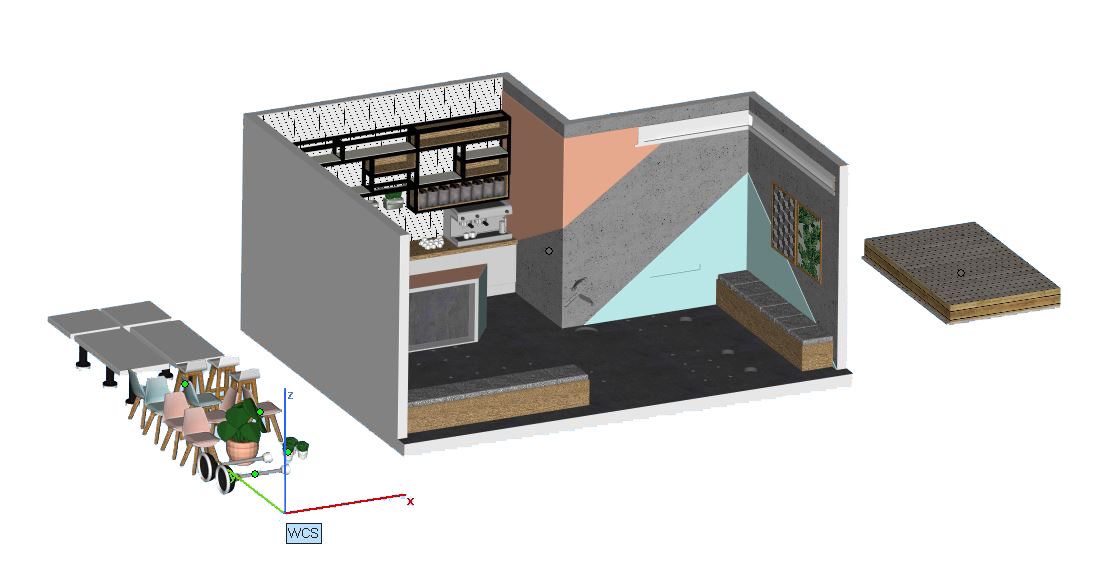

3_SIZING IT UP

Scaling your design to the size it will be replicated at is a useful method for understanding how much time to concentrate on any particular detail. We all get bogged down in making things perfect, but if you realise that the element you’re painstakingly correcting is .1mm when reproduced then you may feel less obliged to put that strain on your eyes.

The first thing we do when fixing a file is to ensure we understand the level of detail we’re looking to print at - this starts with confirming the right scale and size which you can do directly in the viewer.

4_SETTING BOUNDARIES

If the steps above have been followed, then we should be dealing with a clean and easy to assess file. Some key questions remain - what are the extents to the model and if you have a site plug, what is the boundary to this?

The best way to communicate this to us is, coincidentally enough, in 3D - if you draw a box or volume covering the area of the intended print and any plugs, then our software will easily be able to interpret this, we will be able to quickly cut to size without any chance that we’ve missed a key landmark or cut off a relevant adjoining building.

5_PACKING IT UP

Our clients work across all CAD software. Our preference remains the same with each, that we are supplied with one or both of the following file formats:

.OBJ (wavefront)

.FBX (Motion Builder)

.SKP (SketchUp)

Receiving multiple formats is ideal as exports of complicated designs can lead to temperamental outputs. It also allows us to compare these file types if something looks amiss in one, removing the need for multiple emails.

(even though .STL is the recognised 3D printing file format, exporting from your native CAD software to .STL will often not be possible if you haven’t built the model with 3D print in mind - more on how to model for 3D Print)

6_Sending IT ON Its Way

Since you have already saved a new file all you need to do is resave/export the file and upload it to our online platform.

7_WAITING WITH BAITED BREATH

After you’ve specified your project details within our web-app and placed your order, we’ll confirm receipt and approval of the project. If your run into any trouble during the process reach out to us with the in-app chat.

As always, any other questions can we’re here to help.